Cranial remolding orthosis, also known as cranial helmets or bands, is a treatment for infants with cranial deformities. This treatment involves the use of custom-made helmets that gradually reshape the skull of the infant. Recently, 3D printing technology has revolutionized the field of cranial remolding orthosis, allowing for more precise, efficient, and cost-effective solutions. In this blog, we will explore the use of 3D printing in cranial remolding orthosis and the benefits it offers.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a technology that creates three-dimensional objects from a digital file. The process involves building the object layer by layer, using a variety of materials such as plastic, metal, or ceramics. 3D printing allows for the creation of complex, customized, and highly detailed objects with great precision and accuracy.

How is 3D Printing Used in Cranial Remolding Orthosis?

In traditional cranial remolding orthosis, the process of creating a custom helmet involves several steps, including creating a plaster mold of the infant’s head and using the mold to make a custom helmet. This process is time-consuming, uncomfortable for the infant, and can lead to inaccuracies in the final product.

With 3D printing, the process of creating a custom helmet is simplified and improved.

The process of creating a custom cranial helmet using 3D printing involves the following steps:

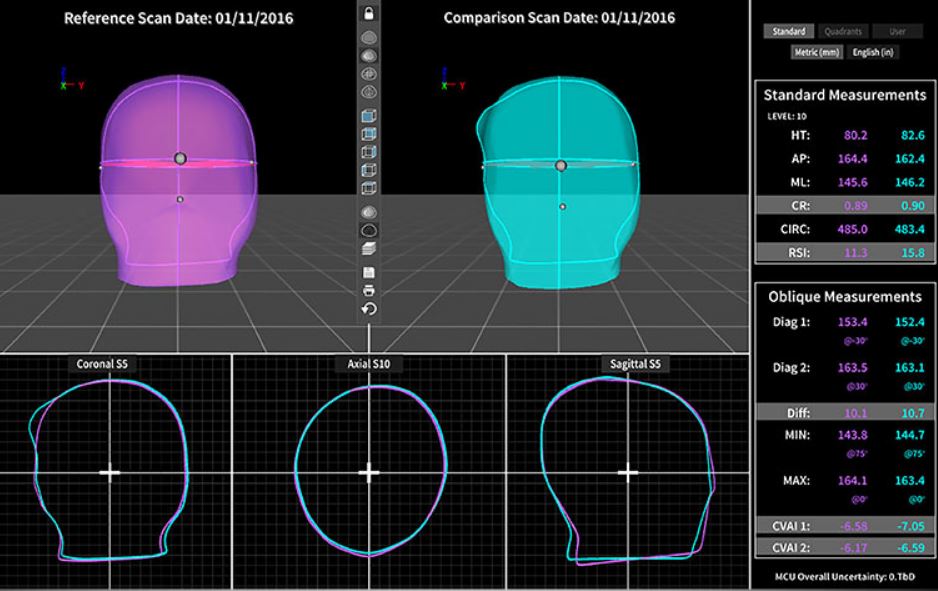

- A scan of the infant’s head is taken using a specialized scanner, which creates a 3D digital model of the head.

- Using specialized software, the digital model is modified to correct the deformity and design the custom helmet.

- The software then generates a digital file, which is sent to the 3D printer.

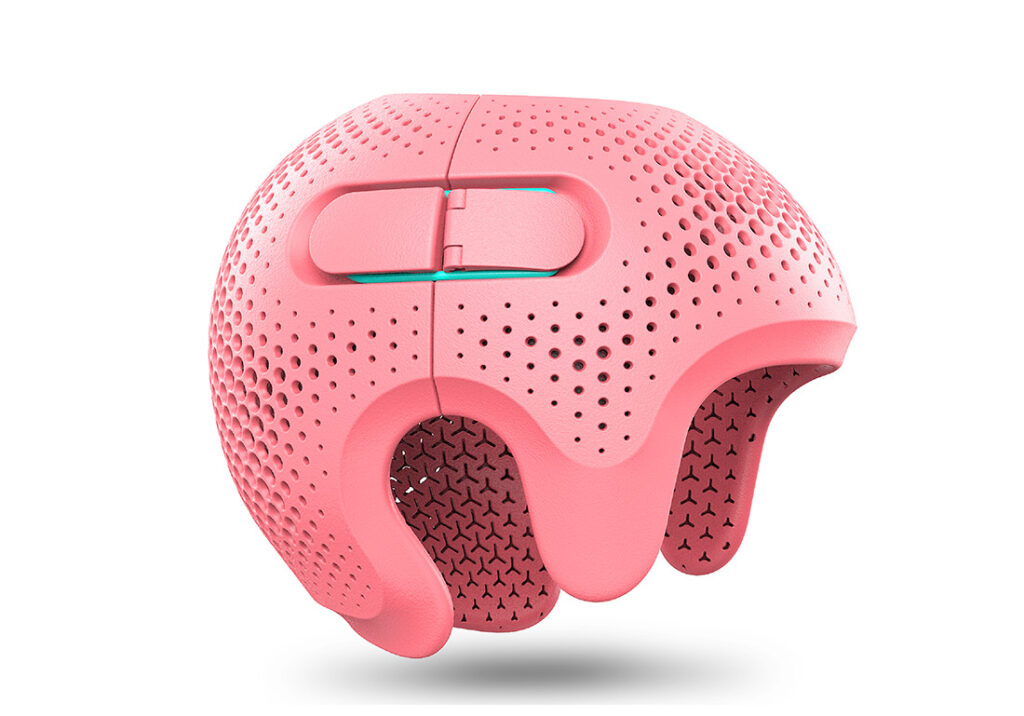

- The 3D printer builds the custom helmet layer by layer, using a lightweight and durable material such as thermoplastic or polycarbonate.

- The custom helmet is then finished and assembled by a trained orthotist, who ensures that it fits comfortably and provides adequate pressure on the affected areas.

IMAGES COURESTY : OAPL, INVENT MEDICAL

Benefits of Using 3D Printing in Cranial Remolding Orthosis

- Improved accuracy:

3D printing allows for more precise and accurate measurements, resulting in a better-fitting helmet that provides the correct amount of pressure on the affected areas. - Customization:

3D printing allows for the creation of highly customized helmets that are tailored to the specific needs of the infant. - Cost-effective:

3D printing allows for the creation of custom helmets at a lower cost compared to traditional methods, reducing the financial burden on families. - Comfort:

3D printing allows for the creation of lightweight and breathable helmets that are comfortable for the infant to wear, reducing the risk of skin irritation and pressure sores. - Faster turnaround time:

3D printing allows for a faster turnaround time from the initial scan to the final product, reducing the amount of time the infant needs to wear the helmet.

3D printing has revolutionized the field of cranial remolding orthosis by providing a more precise, efficient, and cost-effective solution. The use of 3D printing allows for the creation of highly customized helmets that are tailored to the specific needs of the infant, resulting in better-fitting and more comfortable helmets. The benefits of 3D printing in cranial remolding orthosis include improved accuracy, customization, cost-effectiveness, comfort, and faster turnaround time. 3D printing is a promising technology that is transforming the field of orthotics and prosthetics, providing innovative and effective solutions for patients.